Decade old expertise in

Mist Separation

Mist Eliminators – Candle Filters for Chlor Alkali & Sulfuric Acid Plants

Our Services

Within a chemical process plant it is necessary to remove acid mist and droplets from the gas stream which otherwise:-

Damage downstream equipments

Increase atmospheric emissions

Lose valuable acid from the gas stream

Damage downstream equipments

Increase atmospheric emissions

Lose valuable acid from the gas stream

We with our expertise can help you on this.

Suppliers of Equipments

With our experience we can deliver customized solutions that can meet your requirements.

Engineering & Optimisation

Most optimum product design for your new, existing or even aged plant.

Shutdown Delivery Service

Be it any situation we are well equipped for repair and replacements in any reasonable given time span.

CANDLE FILTERS FOR CHLOR ALKALI INDUSTRY

Chlorine, Caustic and Hydrogen can be produced using electrolysis on common salts such as Sodium Chloride and Potassium Chloride. Electrolysis takes place and brine is extracted via Anode and Cathode cells on either side of the membrane.

WET CHLORINE STREAM

Benefits of removing process mist

Optimizes production

Lowers the concentration of water and limits water/moisture carry over

Reduces Sulfuric Acid consumption, in downstream DT application

Minimizes Sodium Sulphate formation in dry chlorine application

Fouling rate of coolers is significantly lowered

Protects downstream compressors and increases product purity

Benefits of removing process mist

Prevent corrosion

Prevent damage to downstream compressor

Higher product purity

DRY CHLORINE STREAM

The recovered chlorine gas from the wet chlorine application will contain moisture. Sulfuric acid is used to remove this moisture in the drying tower. During this process, the fine sub-micron mist is created in the gas stream and passes into the dry chlorine mist eliminator to be removed.

HYDROGEN STREAM

In the cathode compartment, the electrode is submerged in Sodium Hydroxide (NaOH) solution. The hydrogen gas bubbles reach the surface of the solution where the solution is entrained onto the hydrogen to create mist droplets at the exit of the cathode compartment. Following the scrubber, a mist eliminator is used to remove the fine droplets which passed from the scrubber unit. Following this, the clean/dry Hydrogen gas is directed to storage from the mist eliminator unit.

Benefits of removing process mist

Higher product purity

Eradicates or reduces fouling of hydrogen burners for fuel source for hydrogen energy generation

Protects downstream equipment

Prevents damage of compressor & storage tanks

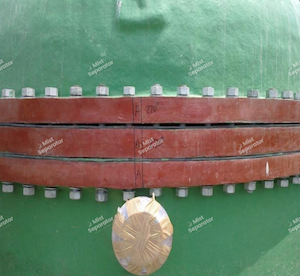

We also have the capability of fabricating Outer Vessels/Tanks to customer drawings for accommodating these Mist Eliminators – Candles in line the process stream. The various MOC we are capable of are Mild or Carbon Steel & Stainless Steel.

CANDLE FILTERS FOR SULFURIC ACID INDUSTRY

Gas stream loaded with fine mist particles will enter the bed of densely packed fibers from one side, while from the other side clean gas will emerge. The liquid separated by either Brownian or Impaction methodology will drain off by gravity.

The liquid separated by either Brownian or Impaction methodology will drain off by gravity.

Number of filters depends on customer requirement on pressure loss and efficiency

Drying Towers normally prefer Demister or Mesh pads as they are easy to install and operate on relatively low pressure lossIn case of Impaction Candles typical media velocities are 1.5 m/sec and design pressure loss is between 100 to 150mm WC

Carbon Fibers are sometimes preferred in applications where HF attacks glassfiber.

The Cages Assembly are fabricated out of a combination of Stainless Steel 316 L/316 material.

Full Face PTFE Gaskets are preferred for tight sealing between the Candle Flange and tube plate surface.

Intermediate Absorption Towers use Brownian Diffusion Candles due to the presence of large amount of submicron mist generated which if not trapped affects the expensive heat exchanger downstream. Typical velocities are 0.15 m/sec and design pressure loss around 150 to 250 mm WC with efficiency of 100% removal of particles > 3 microns.

Final Absorption Towers use either Brownian or Impaction Candles depending on the tower design.

About Us

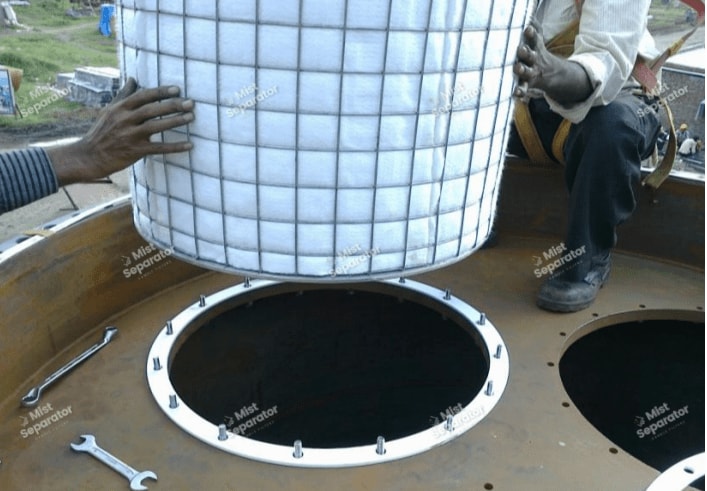

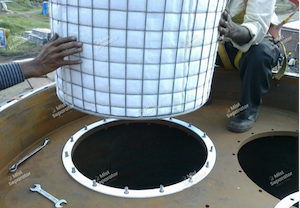

Mist Eliminators or Candle Filters are made out of dense layers of micron size fibers placed between two concentric cylindrical cages.

They are high efficiency separators which are able to collect droplets at submicron level.

They are available in cylindrical shapes and can be manufactured in materials depending on application.

They as a dense packing of filter media assembled between two concentric screens, provided with a flange on top or bottom for installation on a tube sheet.

The elements are in one piece and can be installed through a manhole on the vessel/tower open end.

The Brownian Diffusion type candles use Brownian Diffusion, Interception and Impaction as their collection mechanism and can collect essentially 99.95% of all submicron liquid particles and soluble solid particles. The pressure drop across the elements depend on design.

The Impaction type candles use only inertia based impaction as their liquid removal principle. These types of candles are designed to economically capture droplets in the range of 1-3 micron. The collecting efficiencies at these micron sizes range from 90 to around 97%. The pressure drop across the elements can range depending on the design between 100 to 250mm W.C.

Various fibers used depending upon application are:

Chemical grade Fiber Glass

Polyester

Polypropylene

The Inner and Outer Cages are fabricated in:

Stainless Steel – Sulfuric plants

Stainless Steel - Chlorine plants - Dry Cl2 & Hydrogen streams

Titanium – Chlorine plants - Wet Chlorine stream

Catalogue

Get access to the full list of products we offer, click the button below to access our catalogue

Why Choose Us

Customisable

All parameters are taken into consideration while designing the best possible configuration.

Cost Effective

Good configuration and design ensures to cut down frequent replacements thereby production losses.

Efficiency

Highly efficient liquid removable capacities that can stand tall against the test of times and making it completely hassle-free

Featured Clients

OUR GLOBAL PRESENCE

A Part of

Unicon Group of Companies

Get a callback

Mist Separators India Private Limited

Formerly: Omega Separations India Private Limited